AVISTA Green broke new ground in the summer of 2018 to start the construction of a new high capacity used oil re-refinery at the Port of Kalundborg, Denmark.

The re-refinery is built on the base of our old re-refining plant and has a production capacity of 130,000 tons per year – almost triple capacity compared to the old plant.

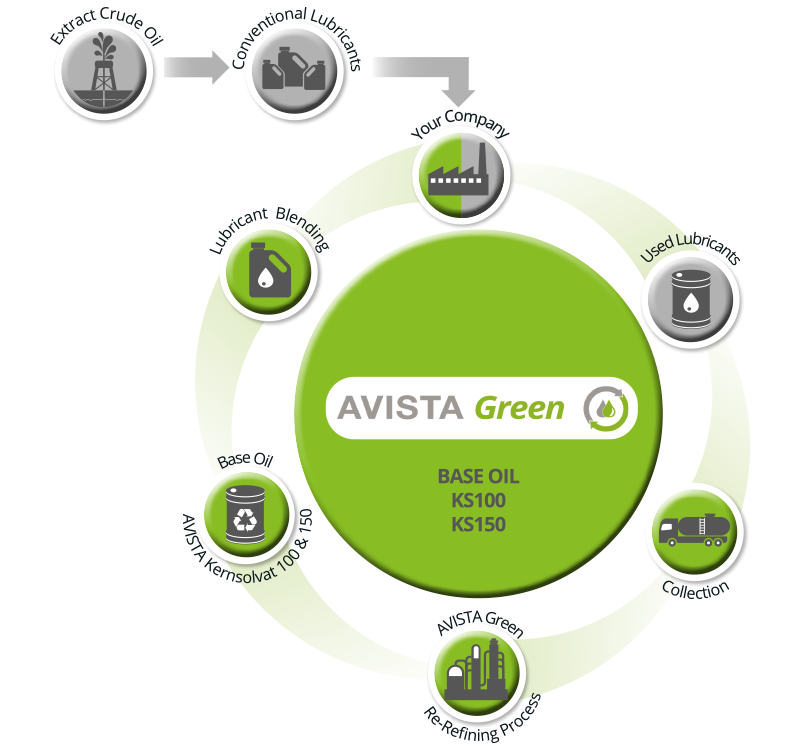

The re-refinery is designed to meet the highest technical standards and to operate by the most advanced technologies. Passing through the processes of the plant, used oil is transformed into high quality base oil ready for reuse in the production of new finished lubricants. In this way, the re-refinery is a major contributor to the global circular economy.

The used oil raw materials for the re-refinery are collected from automotive and industrial companies, the marine industry and waste recovery sites. The substantial volumes are provided by the two shareholders who are leaders in their respective markets. AVISTA OIL with its network of companies is the biggest collector of used oil on the European continent and Greenbottle, through its subsidiary Slicker Recycling, the largest in the UK.

Our business is based entirely on processing a waste product through environmentally friendly processes into a clean product without remnant waste (only water), ready for reuse.

The innovative technology and processes used in our modern re-refinery are far more environmentally friendly and efficient than conventional processes and contribute strongly to sustainability and conservation of resources. Upcycled base oil emits as much as 1450 kg less CO2 per ton than base oil produced from crude oil.

Our business is a natural part of a worldwide growing desire and efforts to preserve and reuse global resources – and in consequence fight climate change. Our vision and mission are fully in line with the intensified focus on green, sustainable solutions.

Our re-refinery is designed for processing used lubrication oil into high-quality base oil ready for reuse in new lubrication oil. Next to the re-refinery, a well-equipped laboratory is ready to handle analyses and future R&D work, just as the re-refinery is prepared for future blending facilities.

The re-refinery with advanced technologies and safety measures operates at a yearly capacity of 100,000 tons of used lubricant oils.

Among the highlights are:

All through the plant, safety for personnel and safety for assets have first priority.

To ensure 100% utilisation of our re-refinery, the supplies of raw materials are guaranteed by our shareholders.

Both shareholders are leading European collectors of used oil and will supply used oil collected mainly in the UK, Denmark and Scandinavia.

Our patented upcycling technology retains the valuable synthetic base oil components of modern, high-quality lubricants: We believe “Extended Selective Refining,” developed by AVISTA OIL, is the leading technology in this sector. Used oil is carefully re-refined using a solvent extraction. At the same time, the valuable, reusable components of the oil are retained.

This helps us make a valuable contribution to environmental protection: The re-refining processes used in AVISTA refineries produce very little waste. The solvent is also refined and reused. The result: Our trademark Kernsolvat® base oil out-performs base oil from crude oil refining according to tests of key performance indicators which are:

AVISTA Fuel F10

AVISTA Bottom Product

For more information about the products, please contact us: sales@avistagreen.dk

Company Name

AVISTA Green ApS

Address

Juelsmindevej 6/18

4400 Kalundborg

Denmark

Customer Service

T: +45 5956 5644

E: sales@avistagreen.dk

Executive Team

Niels Mathiesen, CEO

Tommi Järvinen, Commercial Director

Kirstine Noermark, Technical Director

Lars Christiansen, Finance Manager

Mette Jønsson, HQSE Manager

Peter Jonsson, Project Director

Eva Malling, Head of People & Culture

© 2024 AVISTA Green